during registration.

This service is a continuously sequences which assure our pipeline can be run in optimum condition and safely. Start with Base Line Risk Assessment and ending at implementation, which should be evaluate time after time to generate best and sustainable pipeline operation.

In the maintenance of operations, the protection of installations and equipment is a major issue. This requires rigorous monitoring and great activity to avoid. Due to the reason, PT Wilson Walton Indonesia provides 3X Engineering which offers innovative patented products and high qualified technical services related to pipe repair, tank repair, online leak sealing also pipe and support protection. Furthermore, 3X Engineering always provide design for each repair according to ISO or ASTM standard.

3X

Engineering has developed the repair by using Aramid Fiber (Kevlar), which is

the strongest fiber material but also safe for Cathodic Protection system.

Aramid fiber has adequate modulus strength, which has meaning it is not more

than the metal material itself.

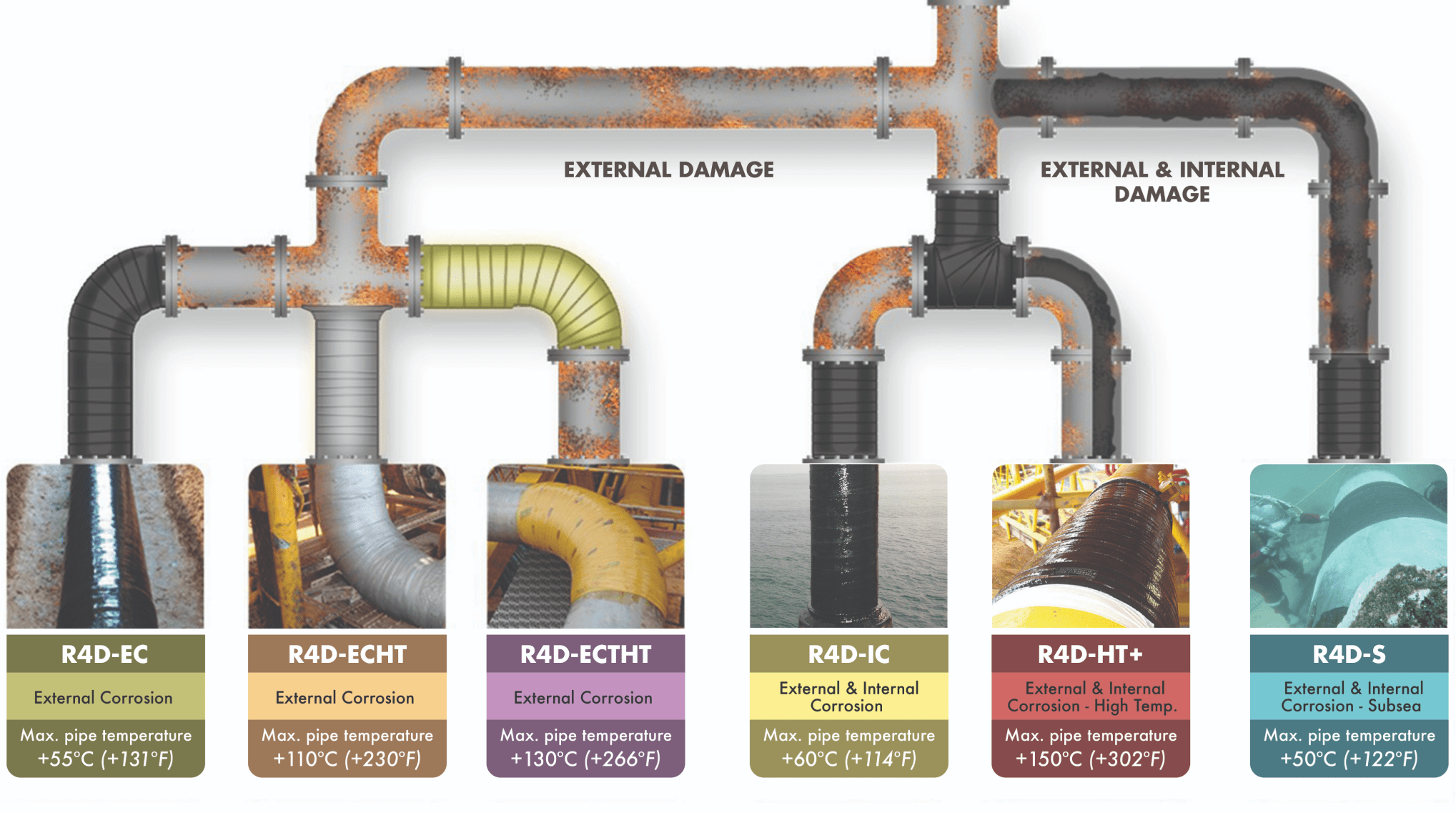

REINFORCEKIT system restores the pipe integrity and prevents from further deterioration. The composite sleeve is made of Kevlar tape and highly-reinforced ceramic epoxy resin. In order to determine repair design and material consumption, software REA provided by 3X will be used to make calculation according to ASME PCC-2, AMSE B31G and ISO 24.817 standards. REINFORCEKIT product is recommended to repair and reinforce pipeline operating which temperature between the range -50°C until +150°C due to external/internal corrosion, leaks, dents and mechanical damages. The solution by 3X Engineering can be applied in subsea repair or underwater application for reinforcement.

Please contact us for any related inquiries.

CONTACT US